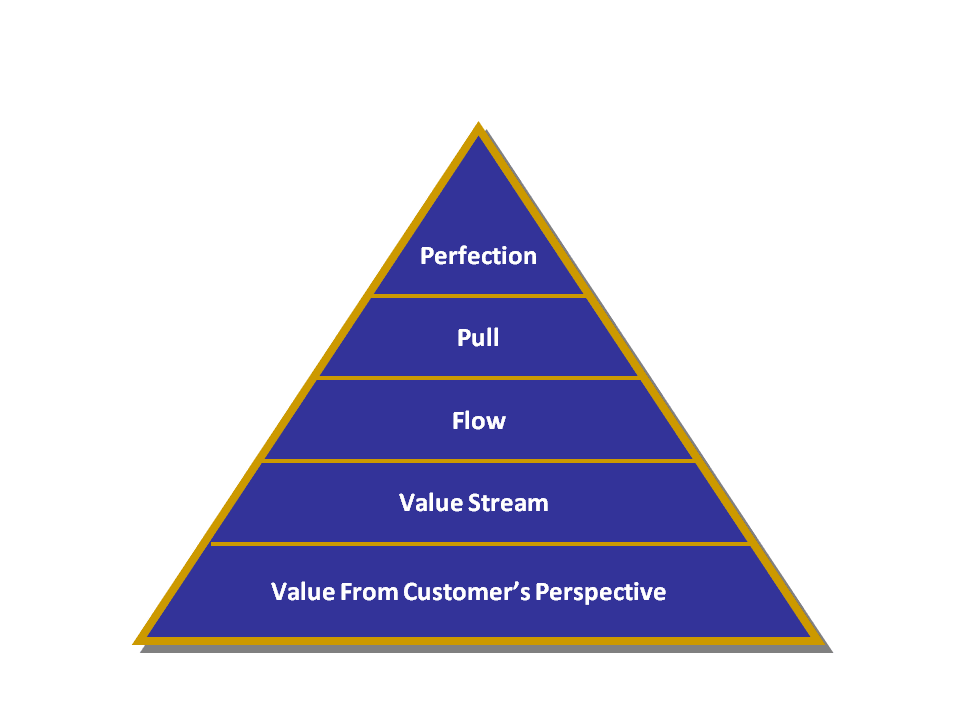

Roadmaps are handy little things, helping to point the direction while on a journey. Sometimes they serve to identify markers on the road letting us know how far along we are, or telling us how far to go to the next marker. The Lean Roadmap provides some general direction to keep our focus forward. Many times we will not get the results that we want when we pick our favorite concept to launch into first. The steps in this map build upon each other to reach the smooth flow of the moving or pulse line. Just like most other efforts we start by talking to our customers and finding out what they like, don't like, and what's important (what is value?). We can make some presumptions about our customers, but we should go talk with them and confirm our beliefs.

Create the Vision

We all know that being able to describe the vision simply or on paper is one of the most important first steps in communicating the vision, and being able to imagine the potential in your organization's operations can put you on the road to good change. Creating the vision may or may not be aligned with your organization's offerings, and the most important question to answer is "how are we creating value for the customer"?

When we measure Product of the 4P's (People, Process, Product, Performance) we are taking a look at the product performance and customer demand. The measure of performance should be based on the requirements or the capabilities the product is sold upon. Customers have expectations about the Product for how it performs today and future enhancements. Does the vision need the Product to be enhanced? This is one part of the Vision. We must also evaluate how our Processes operate, do our People have the skills and abilities for new Products and Processes, and is the Performance good enough to provide the customer the experience that will keep them coming back for more?

Standardize the Flow From Improvements

Once we know where we are going (Future Vision) we need to know where we are starting (Current State) and where is the first marker (Future State). These are high-level maps and metrics describing the Vision and different States. These will be used to target improvements in the flows: product flows, work flows, and cash flows.

Target and reduce the waste and variation. This is the mantra, this is the drumbeat. Everything follows a rhythm and this moves the organization to the next level of performance. Learn from your processes and make changes that can be documented in your SOP's, Policy Statements, and other Work Documentation. Deploy the new learning across the organization and manage the change reaching higher levels of performance. Using a Kaizen approach will be faster, and small steps will be required.

Make the Supplies and Information Point-Of-Use

Improving the flows is not only the transformation steps in process, but creating efficient movement of inputs to the process. Make the material and information inputs easy to find and fast to move. Ensure this is documented in the new process and that everyone is emotionally and physically on board with the new way. Implementing 5S concepts in your operations are focused on organizing and not housekeeping. Organize your material and information in files and on your servers/clients.

Balance the Team

As you make improvement stay aware of bottlenecks in the system. Comparing cycle time to takt time will assist in determining where the help is needed first. Continue this analysis as customer demand changes. Bottlenecks can (and will) move through your system.

Implement Visual Controls and Response

Visual Controls are the metrics, schedule, and constraints posted on the wall or on the displays that the team needs to be aware of. While we may have the vision that says "no more fire-fighting", there should be some recognition that quick action is sometimes needed. Having the signals in place that facilitates this planned response is much better than waiting for the boss to find out from an unhappy customer. This type of system is the foundation of an Employee Empowered Workforce.

Connect Suppliers Using Pull System

Implementing a Pull System is much more difficult and will create much frustration if you have not started improving your flow. Responding only when the order is received (start signal) should keep cash flow high by not spending those dollars on material and labor that will only increase Work-In-Process (WIP). High levels of WIP in your system is just half-built product sitting around waiting to be damaged or made obsolete.

Move/Pulse the Line

We can all envision a Moving Line with Lucy and Ethel inspecting and packaging chocolates. A Pulse Line is one with products that move to the takt time and they have longer cycle times or the cost to automate the transfer is too high. In the places where our office products are created, we can use electronic workflow queuing to move products and to status completion. The "Line" is really a collection of interdependent work teams operating to accomplish a series of tasks. The results are fed back into the Visual Controls and then analyzed for new learning. Using this method will help us to move to higher and more stable levels of performance.

I hope this encourages you to take another look at Lean Flow and how you may use the tools and techniques to improvement customer satisfaction and employee relationships.

No comments:

Post a Comment